In today’s interconnected global economy, supplier management has evolved from a back-office function to a strategic cornerstone of business success. Effective supplier relationships are pivotal in ensuring timely deliveries, maintaining quality standards, and achieving cost efficiencies.

According to KPMG, 50% of supply chain organizations invest in applications supporting artificial intelligence and advanced analytics capabilities to enhance operational efficiency.1

Streamlining fulfillment processes becomes essential as businesses face rising operational costs and heightened customer expectations. It’s not merely about moving products from point A to B; it’s about orchestrating a seamless, responsive supply chain that aligns with organizational goals and delivers value at every touchpoint.

Key Takeaways

- 1

- 2

- 3

- 4

- 5

- 6

- 7

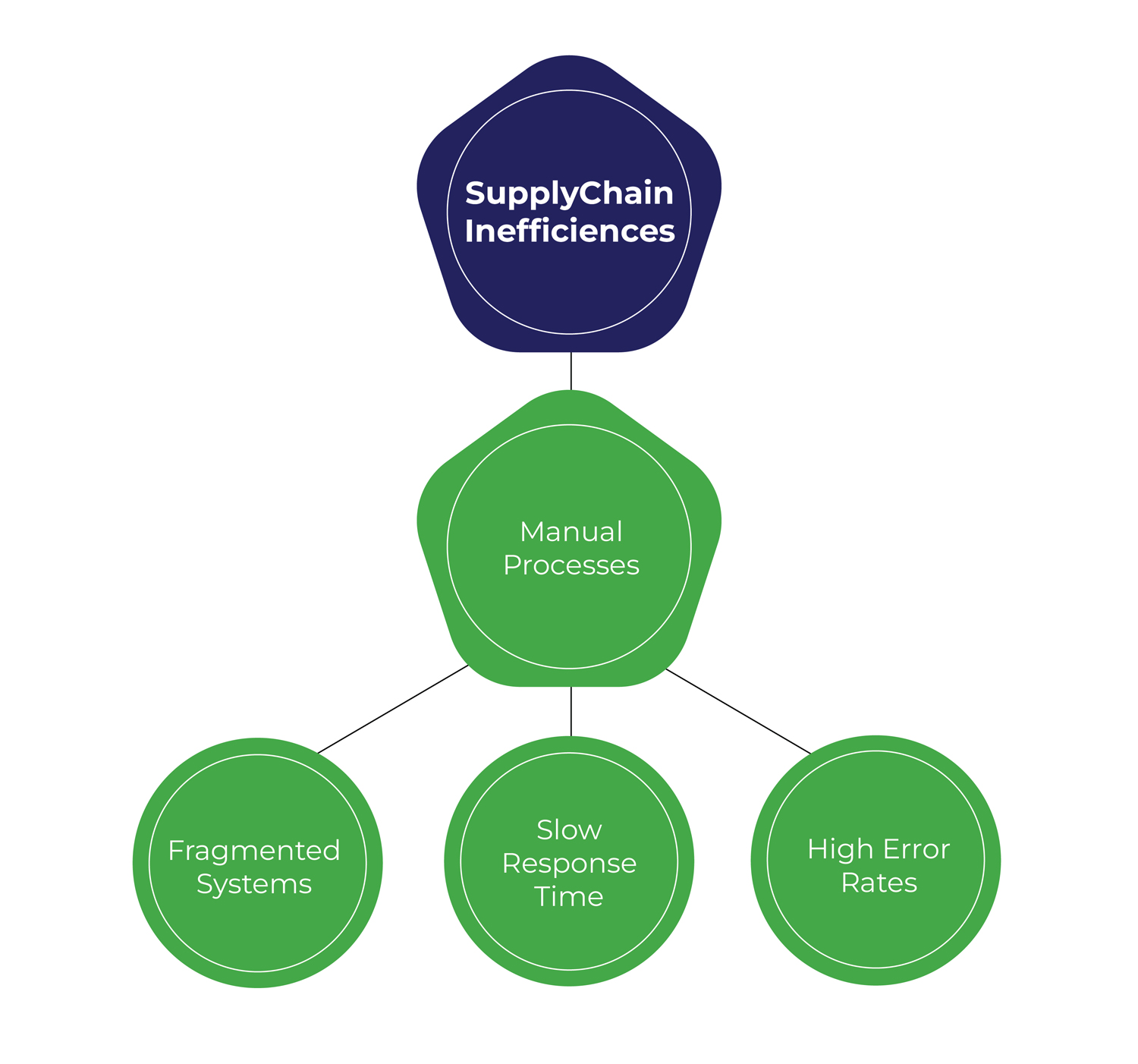

Challenges Undermining Supply Chain Management & Fulfillment Efficiency

Supplier networks are becoming increasingly complex, yet many organizations still lack the visibility needed to manage them effectively. A recent study found that 69% of companies struggle with poor supply chain visibility, leaving them vulnerable to disruptions, stockouts, and missed customer expectations.2 When performance metrics, inventory levels, and order statuses are spread across disconnected systems—or not tracked—organizations can’t respond in real time or plan proactively.

Compounding this issue is the reliance on manual processes. Manual data entry and fragmented systems slow down operations and introduce errors and inefficiencies. Studies indicate that manual data entry can lead to error rates as high as 4%, resulting in significant financial losses and operational delays.3 These inefficiencies are particularly detrimental in high-volume environments where speed and accuracy are paramount.

A Strategic Framework for Supply Chain Management

To overcome today’s supplier and fulfillment challenges, organizations must take a more strategic, structured approach. That means moving beyond short-term fixes and addressing the full supplier lifecycle—from how networks are built to how signals are interpreted to how promises are delivered. The most resilient and efficient supply chains operate on three interconnected pillars:

| Component | Strategic Purpose | Outcome |

|---|---|---|

| Supply Chain Design | Align supply networks with long-term growth and risk models | Business continuity, competitive positioning |

| Planning & Forecasting | Turn market signals into actionable supplier alignment | Cost predictability, optimized working capital |

| Execution Precision | Deliver promises through synchronized operations | Enhanced customer trust, brand reliability |

Strategies to Streamline Fulfillment and Boost Supply Chain Efficiency

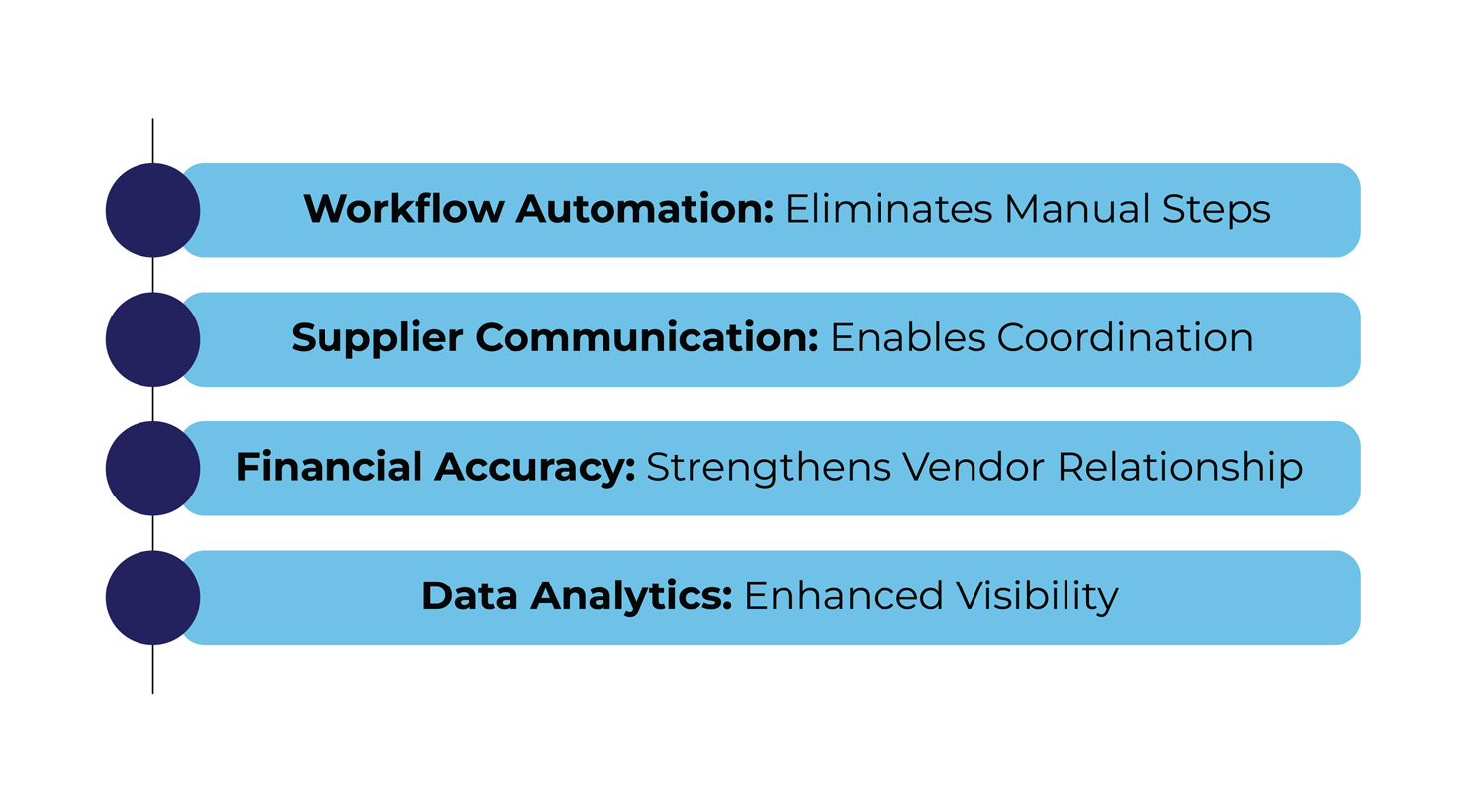

1. Workflow Automation

Manual processes slow fulfillment and introduce unnecessary risk. Automating core supplier workflows—like purchase order processing, inventory updates, and invoice validation—streamlines operations and reduces errors. Workflow automation can cut operational costs by up to 30% while accelerating cycle times and improving accuracy across the supply chain.4

2. Enhanced Supplier Communication

Establishing structured, real-time communication with suppliers is essential to avoid misalignment and delays. Centralized platforms for order updates, issue resolution, and compliance tracking ensure all stakeholders are aligned. Improved visibility across supplier interactions strengthens accountability and supports more reliable delivery timelines.

3. Financial Accuracy

Accurate financial processes are vital for maintaining healthy supplier relationships and ensuring smooth operations. The State of B2B Payments 2024 Report indicates that sectors dealing with high-value transactions often face persistent late payments, impacting cash flow and supplier trust.5 Implementing real-time payment tracking and validation systems can mitigate these challenges, ensuring timely and accurate transactions.

4. Leverage Analytics for Fulfillment Optimization

Data-driven supply chains outperform reactive ones. Leveraging data analytics provides visibility into supplier performance, inventory flow, and risk indicators. This enables proactive decision-making, allowing businesses to adjust sourcing and fulfillment strategies before issues escalate.

Why Strategic Outsourcing Supports Supply Chain Optimization

While automation, supplier communication, financial accuracy, and data analytics are essential for fulfillment optimization, many organizations face significant internal barriers when implementing these strategies. Common limitations include resource constraints, fragmented systems, and the need for specialized expertise to scale initiatives effectively.

Strategic outsourcing—particularly through co-sourcing models—offers a practical path forward. Rather than functioning as an external vendor, a co-sourcing partner operates as an integrated extension of internal teams, aligning with operational goals and embedding support where needed most.

Key advantages of this approach include:

- Accelerated technology enablement

- Continuous process execution

- Access to specialized skills

- Scalability

- Improved coordination

Premier NX: Enabling Streamlined Fulfillment & Efficient Supplier Execution

Premier’s co-sourcing model embeds dedicated global teams aligned to your operations—combining process ownership with domain specialization. Premier NX helps you close execution gaps across supplier management, finance, and fulfillment by activating the strategies outlined above through our integrated service pillars:

- Digital Transformation (DX) – Premier implements automation, unifies workflows, and modernizes legacy systems to eliminate friction in supplier and fulfillment cycles.

- Analytics & Insights – Our teams turn real-time supplier and fulfillment data into predictive intelligence, helping you act proactively—not reactively.

- Finance & Accounting (FinOps) – We ensure financial precision across procurement and vendor transactions, reducing delays and improving cost visibility.

From improving vendor communication to enabling accurate, on-time fulfillment, Premier NX brings the scale, infrastructure, and execution support needed to operationalize your supply chain strategy—without overloading internal teams.

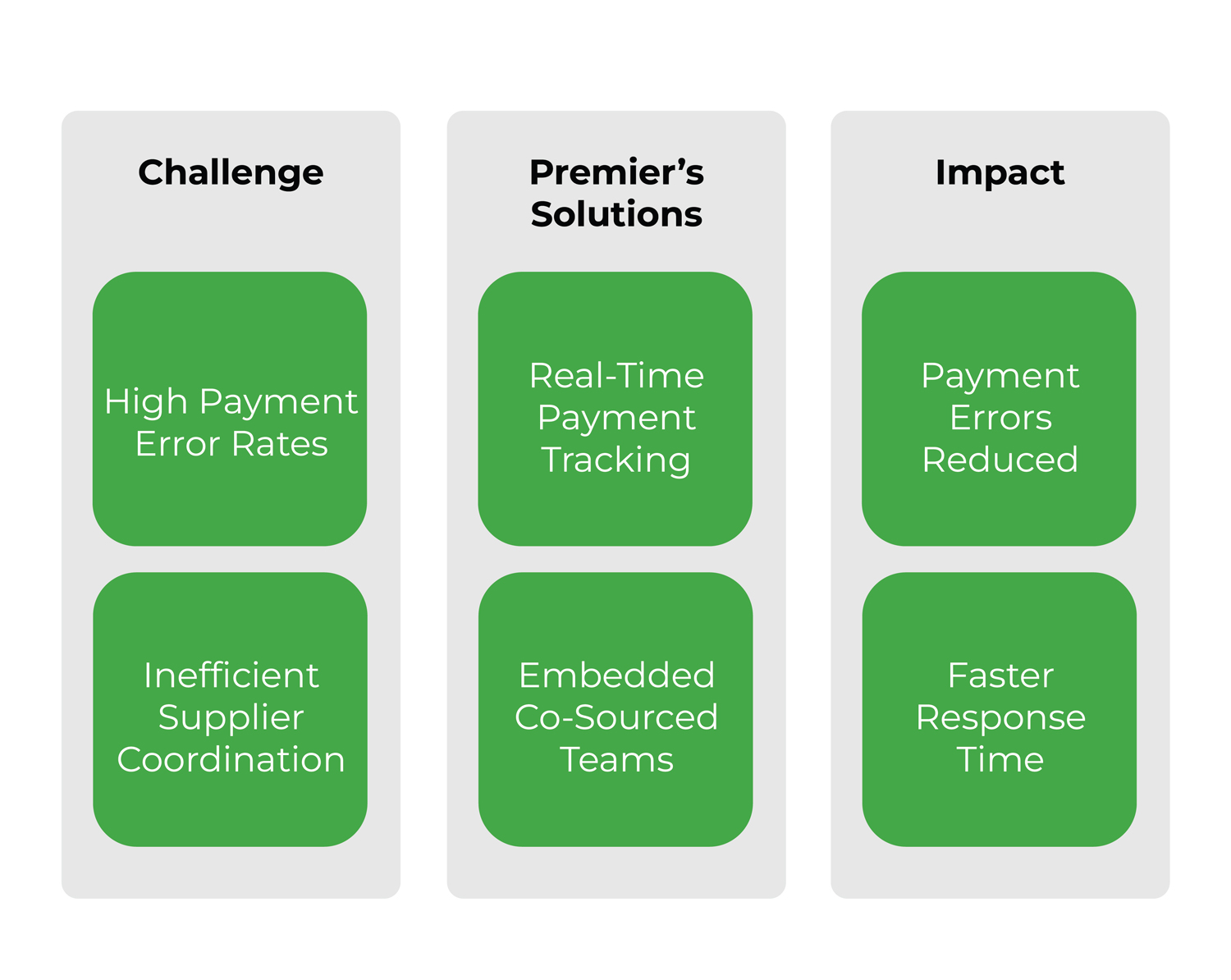

Case Study: Driving Fulfillment Efficiency for a Leading Equipment Rental Marketplace

Client Challenge

An equipment rental marketplace was facing critical breakdowns across its supplier coordination and fulfillment operations. After an unsuccessful outsourcing engagement, the organization dealt with inconsistent service quality, high payment error rates, communication overload across supplier channels, and a lack of structured monitoring across its support functions.

Our Co-Sourcing Intervention Included:

- Specialized teams embedded across fulfillment, dispatch, finance, and customer support

- Realignment of workflows to separate call, email, and back-office responsibilities

- Implementation of real-time payment tracking and audit processes

- Deployment of a modern CX platform to enhance interaction quality and performance visibility

Measured Impact

- Payment error rates reduced

- Stabilized high-attrition teams with workforce continuity plans

- Achieved top-tier service ratings across all business lines

- Improved response time, supplier alignment, and overall fulfillment reliability

Achieve Efficient Supply Chain Management with Premier NX

Optimizing supplier management and fulfillment is not just a function of good strategy—it’s about activating that strategy with precision, agility, and control. From workflow automation and supplier communication to financial accuracy and data analytics, execution is where true impact happens.

Premier NX helps supply chain leaders bridge the gap between vision and results through our co-sourcing model, digital operations expertise, and integrated service pillars.

Connect with Premier NX to explore how our Digital Transformation, FinOps, and Analytics services can power your supply chain optimization efforts.